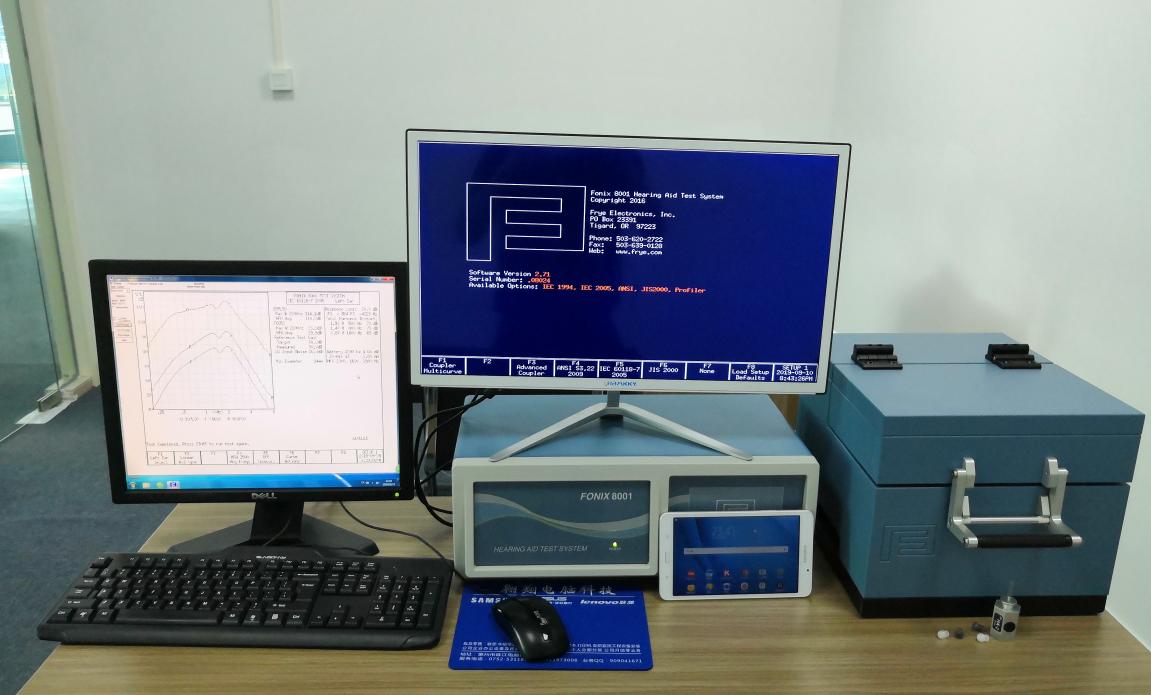

What’s the hearing aids testing system work for?

A hearing aid testing system is featuring the unique Polar Plot Sound Chamber, capable of performing automatic polar plot measurements of directional hearing aids. Although the results are not a replacement for laboratory testing using an anechoic chamber.

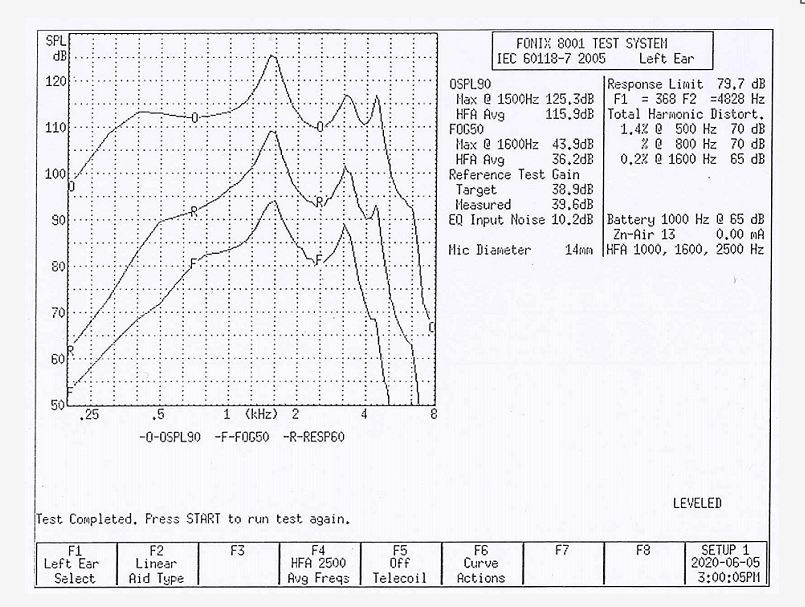

Max OSPL

The nominal value of the manufacturers product standards or specifications, the actual test value should not be greater than nominal values+3bB.

Average OSPL

Nominal value by manufacturer“Product standards or technical specifications, the actual test value tolerance is better than 4dB.

Nominal value by manufacture“Product or technical specifications, the actual test frequency average deviation of 5dB.

EN-T100 BTE hearing aids testing requirments and testing method

Mechanical properties one Plugging force Conditions: at the speed of 12.5mm/min, record the data after plugging in and out for 5 times continuously, and the five data tested meet the requirements of the association. N 1PCS Plugging force testing machine.

Judgment standard: USB type: insertion force F ≤ 35n; Pullout force 10N ≤ f ≤ 35n.

two Plug life Conditions: USB class: 1500 times of plugging at 200times / h speed N 1PCS Life testing machine.

Judgment standard: the performance meets the requirements of the association and the product can work normally.

Three Switching life Conduct on-off action on the switch at the speed of 30 times / min. after 20000 times, the test switch can work normally. second 1PCS Switch life tester.

Four Monomer drop test The sample single product (single product scattered under gravity) falls freely from the height of 150cm to the iron plate or cement floor with material thickness of 2.54cm for 10 times. After the experiment, the product function is normal, and the product shall not crack or have abnormal noise caused by metal objects. CM 1PCS Drop tester.

Five Simulated transportation vibration test With the amplitude of 25.4mm and the speed of 150rpm / min, the product can work normally after the test. H 2PCS Simulated transportation vibration testing machine.

Electrical characteristics six Quiescent current The static current of the product is less than the upper limit of the specification. mA 3PCS ammeter December

seven Short life test After continuous operation at 40 ℃ for 168h, the appearance and performance of the product did not change during the experiment. - 3PCS Sound source

eight Internal resistance of battery The internal resistance test value of the battery meets the specification value. mΩ 3PCS Internal resistance tester December

nine Forced discharge test After discharging the battery according to the manufacturer's regulations, charge it in reverse with 1C current for 90min, and the battery shall not catch fire and explode. min 1PCS Volume dividing cabinet

environmental test ten High temperature and humidity storage Store it in the environment of high temperature 60 ℃ and humidity 95% for 72h. After the experiment, the test function is normal and the appearance is normal after 0.5h at room temperature. H 1PCS Constant temperature and humidity machine

eleven Low temperature storage After being placed at - 40 ℃ for 24h and at room temperature for 0.5h, the function and appearance of the product shall be tested without abnormality. H 2PCS Constant temperature and humidity machine

twelve Damp heat action test After the test at room temperature and humidity of 40.0% for 5h, the appearance is normal. H 2PCS Constant temperature and humidity machine

thirteen Low temperature action "1. At low temperature - 20 ℃ for 96h, after the experiment, stand at room temperature for 0.5h before testing;

2. The product function and appearance structure are normal. " H 3PCS Constant temperature and humidity

fourteen UV Test The product was placed in a UV lamp box with a temperature of 20-35 ℃ and placed under the lamp tube with a UV lamp wavelength of 300 ~ 420nm and a power of 2x15w for 72h. After the test, the product material did not crack or seriously turn yellow. H 1PCS UV light box

EN-I102 hearing aid reliability test

Inspection items Standard requirements Company Number of samples Method / equipment

Mechanical properties one Plugging force Conditions: at the speed of 12.5mm/min, record the data after 5 times of continuous plugging, and the three data tested meet the specifications of the association. N 1PCS Plugging force testing machine

Mirco type: insertion force F ≤ 35n; Pull out force 8N ≤ f ≤ 25N

two Plug life Micro type: after plugging 10000 times at the speed of 12.5mm/min, the performance meets the requirements of the association, and the product can work normally. N 1PCS Life testing machine

three Key life test With 300g force and the speed of 30 times / min, conduct on-off action on the key. After 20000 times, the test key can work normally. second 1PCS Key life tester

four Monomer drop test The sample single product (single product scattered under gravity) falls freely from the height of 150cm to the iron plate or cement floor with material thickness of 2.54cm for 10 times. After the experiment, the product function is normal, and the product shall not crack or have abnormal noise caused by metal objects. CM 1PCS Drop tester

five Simulated transportation vibration test With the amplitude of 25.4mm and the speed of 150rpm / min, the product can work normally after the test. H 2PCS Simulated transportation vibration testing machine

Electrical characteristics six Quiescent current The static current of the product is less than the upper limit of the specification. mA 3PCS ammeter

seven Short life test After continuous operation at 40 ℃ for 168h, the appearance and performance of the product did not change during the experiment. - 3PCS Sound source

eight Internal resistance of battery The internal resistance test value of the battery meets the specification value. mΩ 1PCS Internal resistance tester

nine Battery capacity Divide the capacity of the battery according to the standard requirements, and the capacity of the divided capacity meets the requirements of the specification. mAH 1PCS Battery capacity distribution cabinet

ten Forced discharge test After discharging the battery according to the manufacturer's regulations, charge it in reverse with 1C current for 90min, and the battery shall not catch fire and explode. min 1PCS Volume dividing cabinet

environmental test eleven High temperature and humidity storage Store it in the environment of high temperature 60 ℃ and humidity 95% for 72h. After the experiment, the test function is normal and the appearance is normal after 0.5h at room temperature. H 2PCS Constant temperature and humidity machine

twelve Low temperature storage After being placed at - 40 ℃ for 24h and at room temperature for 0.5h, the function and appearance of the product shall be tested without abnormality. H 3PCS Constant temperature and humidity machine

thirteen Damp heat action test Under the high temperature of 40 ℃, humidity of 90% and working condition of 48h, after the experiment, stand at room temperature for 0.5h, and then test whether the function and appearance are normal. H 3PCS Constant temperature and humidity machine

fourteen Low temperature action "1. At low temperature - 20 ℃ for 96h, after the experiment, stand at room temperature for 0.5h before testing;

2. The product function and appearance structure are normal. " H 3PCS Constant temperature and humidity machine

fifteen UV Test The product was placed in a UV lamp box with a temperature of 20-35 ℃ and placed under the lamp tube with a UV lamp wavelength of 300 ~ 420nm and a power of 2x15w for 72h. After the test, the product material did not crack or seriously turn yellow. H 1PCS UV light box